Linear motion in packaging plays a crucial role in production processes, ensuring precision, durability, and corrosion resistance to maximize operational efficiency. As production lines evolve towards more advanced solutions suited to demanding environments, having robust, high-performance guiding systems is essential.

Within this context, HepcoMotion’s SL2 guides provide an advanced solution for applications requiring optimal performance in challenging conditions. These guides are designed to withstand rigorous industrial environments, ensuring reliability in sectors such as food, pharmaceutical, medical, and cosmetics, where regulatory and quality demands are particularly high.

Technical Features

SL2 guides are manufactured from hardened stainless steel, offering excellent corrosion resistance. Their modular design allows for versatile integration into a wide range of packaging applications, providing scalable solutions tailored to different production needs.

Additionally, HepcoMotion’s signature V-guide system significantly reduces friction and wear, ensuring smooth and precise movement over time. This technology not only enhances operational efficiency but also lowers costs related to maintenance and component replacement, resulting in greater profitability for companies in the sector.

Advantages of the SL2 System

SL2 guides offer multiple benefits that make them an ideal choice for the packaging industry:

- Corrosion Resistance: Made from stainless steel, these guides can operate in humid or aggressive environments, cleanrooms, and washdown areas without compromising performance.

- Versatility: Available in lengths of up to 4 meters, with the option of extending configurations using paired guides for custom setups based on production needs.

- Lubrication Options: HepcoMotion offers various lubricants specifically designed for sensitive environments such as the food industry, cleanrooms, vacuum applications, or extreme temperatures.

- Low Maintenance: The V-guide technology reduces maintenance requirements and ensures long service life.

These factors make the SL2 system highly competitive in the sector, providing a robust and efficient solution for linear motion in packaging.

Want to stay updated on the latest in the packaging sector? Subscribe to our newsletter!

Applications in the Packaging Industry

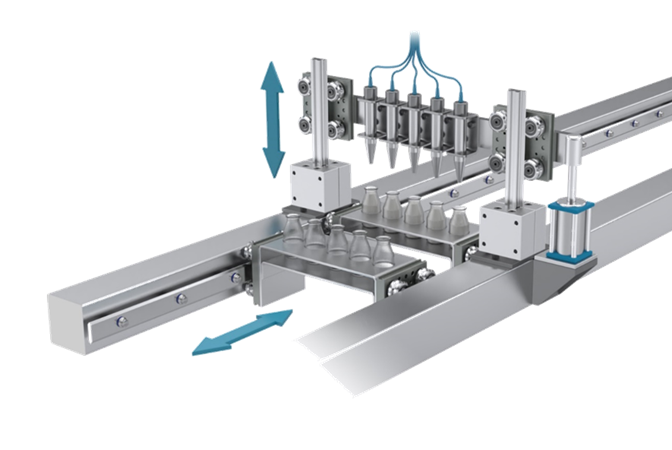

SL2 guides are perfectly suited to the requirements of the packaging industry, where precision and reliability are essential for maintaining operational efficiency and meeting the highest hygiene standards. Their versatility makes them ideal for various industrial applications:

Food Packaging Machines

In the food industry, hygiene and safety are critical aspects. SL2 guides ensure precise and safe operation, reducing contamination risks and ensuring compliance with sanitary regulations. They guarantee the hygiene and corrosion resistance needed for food processing.

Medical and Pharmaceutical Equipment

The manufacturing and packaging of pharmaceutical products and medical devices require high accuracy and reliability. SL2 guides provide precise linear motion without deviations, essential for maintaining product quality and consistency throughout the process.

Cosmetic Applications

The cosmetics sector demands solutions that combine durability and precision for handling and packaging high-quality products. SL2 guides ensure an efficient workflow and minimize the risk of mechanical failures, helping maintain continuous and uninterrupted production.

Performance and Production Benefits

Linear motion plays a crucial role in optimizing packaging processes. With their innovative design and advanced features, HepcoMotion SL2 guides provide the perfect balance between performance, durability, and reduced maintenance, making them a highly efficient solution for companies looking to enhance their production lines.

From container filling and handling to labeling and final packaging, these guides ensure smooth and precise movement at every stage of the process, increasing productivity and minimizing downtime.

At Barcelona Packaging Hub, we are committed to innovation and excellence in every industrial process. We collaborate with top-tier technology partners like HepcoMotion to provide our members with advanced solutions for optimizing linear motion in packaging.

Through this synergy, we help companies in the sector improve their production line efficiency, reduce operating costs, and maintain high-quality standards, reinforcing innovation as a key pillar in packaging evolution.

The integration of advanced technologies like SL2 guides not only enhances equipment performance but also provides greater flexibility in adapting to current industry challenges, driving digital transformation and competitiveness in the global market.