The packaging industry needs flexible, efficient, secure and interconnected solutions in order to get the maximum information from the systems. Bonfiglioli, Barcelona Packaging Hub’s new technology partner, offers customized and versatile solutions that offer installation and energy savings. In this article we present several examples and real case data on these solutions and their energy savings.

David Peribáñez, Business Developer M&R and Manel Sala, Product Engineer D&P

Energy efficiency is one of the most important values in industrial solutions today. The change in European eco-design regulations, as well as the constant increases in energy prices, have pushed us to work with much more efficient solutions with references that translate into savings for both machinery manufacturers and end users.

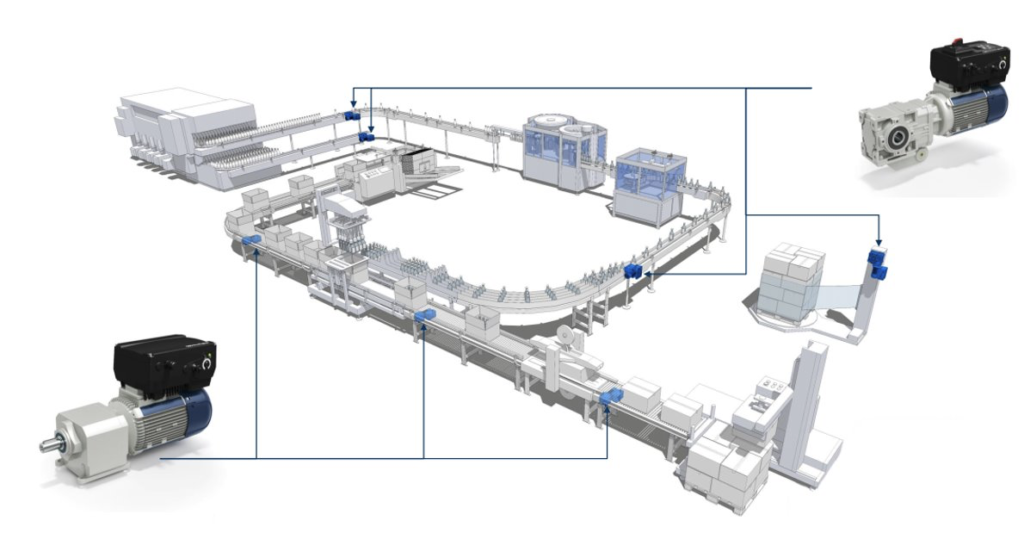

In the packaging sector, Bonfiglioli works with applications that meet all these requirements, as well as being versatile applications to suit the needs of its partners to achieve the exact result for their requirements.

What formulas does Bonfiglioli offer?

- IEC reluctance motors combined with industrial gearboxes.

- Reluctance motor offers constant torque at 0Hz, reduced casing for the same power as in asynchronous, dynamics, reduction of consumption/installed power and no dependence on the cost of magnets.

- Gearboxes with orthogonal output and mechanical backlash < 7″.

- Servomotors with “S” flanges for easy adaptation to industrial gearboxes.

- Coaxial CP asynchronous motors and in-line gearbox.

- Precision gearboxes with high adaptability in inlet/outlet flanges.

- Precision reducer integrated in servomotor (with the consequent reduction of space).

- Decentralized inverters on motor or wall-mounted, multi-protocol, operating for asynchronous, reluctance, servomotor and fully configurable.

What is the impact of Bonfiglioli solutions on energy efficiency?

To present it in a more graphic way, we base it on a real case: using a 1.5kW asynchronous motor as a reference. a four-month ROI would be achieved by switching to a reluctance motor, given the current situation of high energy costs. As they are fully compatible engines as far as the mechanical interface is concerned, the changeover is plug&play and the virtues it presents are remarkable.

If we refer to the decentralized drives and take into account an installation of 40m2, where they originally had 15 drives (0.55kW-3kW), 3 inductances, 2 Dv/Dt filters and 5 EMC filters.

In redoing the project with the Bonfiglioli proposal, we eliminated or reduced the following materials:

- The electrical cabinet is 2000x1600x400mm. 600x600x250mm.

- The motor cable is eliminated.

- Inductances are reduced and motor Dv/Dt are eliminated.

- 1x Motor guard for assemblies of up to 6 Drives using STO as a controlled stop.

- Installation hours are reduced by up to one third.

- In addition, any operator can install the equipment (Harting and M12).

In this case, the reduction, applying the above points, was 21% in the total cost of the project. If we add the energy cost savings due to the reduction of the installed power, this percentage increases, so it becomes a solution that means savings for the machinery manufacturer and also for the end customer who, with our solution, obtains an efficient application that results in a better energy cost.